What Can A Rubber Recycling Plant Do?

- By zhou qi

- •

- 11 Jul, 2019

The rubber recycling plant is available in different capabilities based on the amount of resources readily available and initial investment which the customer can manage. The smaller plants are of batch kind, and also they will be used only for some hours a day, based upon the raw product offered. These devices appropriate for customers who can spend less, as well as the earnings is additionally lower given that the heater needs to be heated up everytime the maker is begun. For higher earnings, a semi constant or continual device is liked, though the investment is greater as well as the customer has to ensure a continual supply of resources.

A driver with different components is used to improve the processing and also reduce sulphur web content. After a temperature of 100 degree centigrade is gotten to, fuel gas is produced. As the temperature level is boosted numerous fuel gases are created. Dust collection agencies and also cyclone are made use of to eliminate the dust and other pollutants in the oil. These gases are after that gone through a manifold and also the gas will liquefy to form oil. This fuel oil is then offered to buyers, used in diesel generators to improve burning, utilized a fuel for the furnace, or distilled to transform it right into diesel and also fuel. More information can be found: www.bestonasia.com.

The various other basic material which is created from the pyrolysis of rubber is carbon black as well as fuel oil. The carbon black is made use of for making master batches for paint as well as other tinting product. It can be also processed into coal or sold. The combustible gas which is produced is made use of for heating up the heating system or is offered. So the procedure of pyrolysis of scrap rubber is very eco-friendly considering that there is no waste material created, which need to be gotten rid of. All the items can be sold for an earnings by the machine owner, or used for the processing of waste rubber.

It needs to be kept in mind that the quantity of oil generated from waste rubber, depends to a large level on the kind of waste rubber which is being made use of. When the rubber is made into different products, the additives and also rubber structure will vary, and when these items are ditched, processed in a furnace, the products which are obtained will certainly vary to a fantastic degree. As an example, oil gotten from submarine cables will certainly be 75% by weight, while the oil yield when shoes soles are made use of will be 30% or somewhat a lot more. Hence the buyer of the equipment must look for suitable rubber scrap resources.

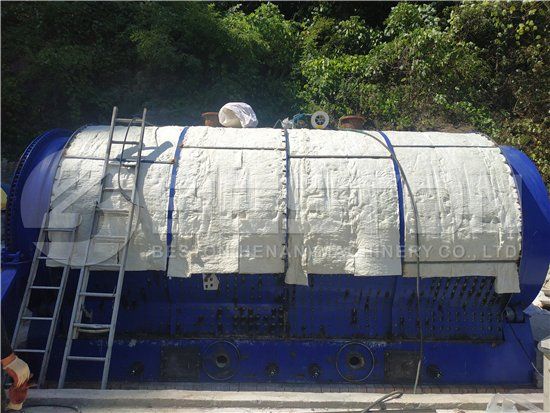

For an everyday capacity of up to 10 tonnes, set type rotating pyrolysis plants (https://bestonasia.com/pyrolysis-plant/) are typically used. The heating system size and also length will enhance depending upon their ability. Different types of resources like charcoal, timber, flammable gas, oil can be made use of for heating the heater depending upon the availability. Water air conditioning is utilized for cooling all the ended up products. Normally each device will last for five to 8 years. The maker manufacturer will certainly install the equipment at the clients factory, as well as also educate the personnel. They will likewise occasionally inspect the equipment, as well as make certain that there is not a problem.