Introduction to A Top Rubber Pyrolysis Plant Manufacturer In China

- By zhou qi

- •

- 04 Dec, 2019

To be honest that nowadays in this era, waste rubber presents a significant environmental concern for a lot of countries. When waste tires are sent to landfill sites, by way of example, they consume much space and might dominate 80 years to decompose since rubber is not really biodegradable. Furthermore, toxic chemicals from the decomposing tires can leak through landfill site liners and contaminate soil and groundwater. When waste tires are brought to incinerators for disposal, lots of energy and also heat might be harnessed from them, nevertheless the burning process put plenty of pollution in to the atmosphere. Fortunately, together with the latest rubber pyrolysis technology, scrap tires may be transformed into lucrative commodities without the harm to the environment.

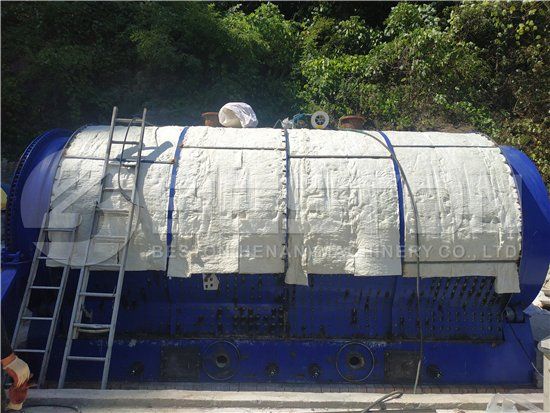

The science behind the pyrolysis process is pretty simple. The process is basically merely a chemical reaction facilitated by extreme temperatures and the absence of oxygen. When rubber is heated to extremely high temperatures in an oxygen-free chamber, it vaporizes as an alternative to burns which implies no smoke or pollution is produced. When the vapor is sent by way of a condensing system, fuel oils of varying viscosities might be collected. The ideal pyrolysis machines are engineered to get a service life as much as eight years. Operators can prolong the lifestyle of pyrolysis machines by removing all of the steel wire from scrap tires before they can be fed into the main reactor.

In addition to being capable of recycle waste tires having a rubber pyrolysis plant, other rubber materials can also be processed including rubber hoses, rubber shoes, telephone wire, submarine cable, etc. The four main waste rubber pyrolysis machine models on the market fromBestonwould be the BLJ-6, BLJ-10, BLJ-16, and BLL-20. The BLL-20 model has a daily capacity of 24 tons, meaning it can be used to process a great deal of waste rubber daily.

Some of the basic parameters utilized to compare different pyrolysis machines on the market include daily capacity, reactor size, working method (batch, semi-continuous or fully continuous), total power, operating pressure, floor area, and cooling method. The price of pyrolysis plants is usually connected to the size of the reactor and consequently the most daily processing capacity. The larger the reactor size, the bigger the asking price. The good thing is that this ROI on any sized pyrolysis machine is quite high, as fuel oil is actually a profitable commodity and there is no shortage of waste rubber awaiting processing in several regions. Making an investment in pyrolysis technology is now a profitable business enterprise for most entrepreneurs in developing countries.