How To Buy A Waste Sorting Machine

- By zhou qi

- •

- 18 Mar, 2020

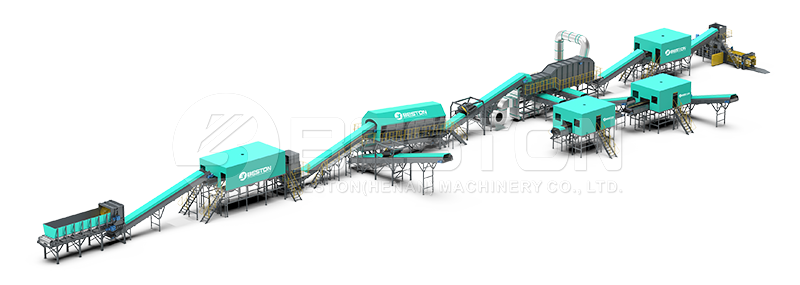

Getting a waste sorting machine isn't as easy as selecting a reliable supplier and ordering the best equipment you can afford. You should conduct an in-depth research and a thorough analysis of your respective market before knowing what sort of machine to choose. This informative article takes a closer inspection in the waste sorting process, to ensure that you to understand what sort of equipment would best meet your needs.

To start with, you have to be conscious of you'll be dealing with several categories of waste. You'll must separate metal items from plastic, rubber, paper, and constructions materials. You'll have to deal with organic matters, along with with sharp products which may deteriorate your conveyor belts along with your other devices.

As a way to extract metals in the bulk, you'll want a powerful magnetic extractor. Copper also requires special equipment that generates a magnetic field which helps extracting items produced from this metal and send these people to another conveyor system.

As most garbage comes in plastic bags, any waste sorting line needs to incorporate a plastic bags remover. Although human workers can manually remove these bags, automation will enable you to score a much better productivity, and for that reason a better profitability rate. Furthermore, an automatic waste segregation machine could work almost twenty-four hours a day, without the need for paid leave or vacation days.

Centrifugal modules are able to separate recyclable and non-recyclable plastic items, to be able to send them for more processing. Centrifugal separation has an excellent accuracy. The procedure is simple to control by selecting the appropriate diameter for that holes that let smaller items go through.

An efficient garbage sorting machine needs another compacter along with a baler. The compacter helps to ensure that materials are compressed so that you can take less room. The baler creates compact bales which are quicker to store and transport than the various waste items to be recycled. Besides, by compacting garbage before it enters the separation and recycling process, you can avoid damages to conveyor belts.

Finally, any waste sorting line requires several conveyor systems, so that you can move materials in one stage of the process to the next. The choice of conveyor belts depends upon the kinds of materials to get transported. Heavy items, for instance, require metal belts and really sturdy systems. Plastic and lighter materials require rubber belts.

As we discussed, setting up a waste management recycling plant can be a complex endeavor which could involve the task of countless technicians and experts. The style of the conveyor system and choosing the numerous modules is likely to make the visible difference between an effective and efficient system along with a low productivity one.