Buying A Wood Charcoal Manufacturing Machine

- By zhou qi

- •

- 13 May, 2020

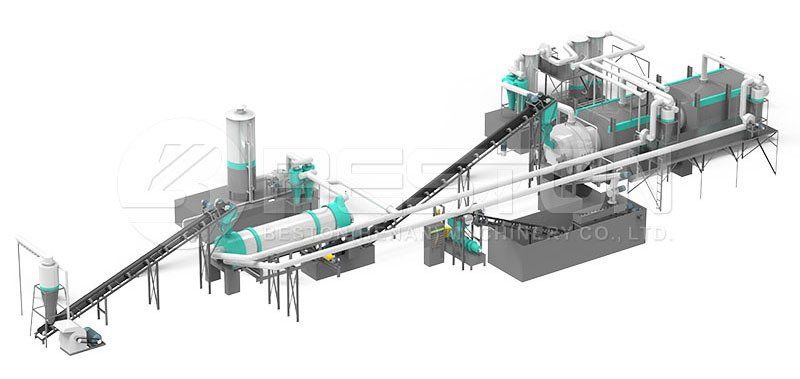

A high-line wood pyrolysis plant utilizes advanced carbonizing technology to change wood chips into charcoal etc plants attract plenty of foreign buyers. You can find great opportunities to purchase developing wood recycling and biochar fuel markets in lots of countries. After all, from the wood recycling industry, initial investments required are low, while returns can be very high.

Top Manufacturers

The reasons why many manufacturers use a great reputation in the wood charcoal manufacturing machine market is simply because they supply high-quality equipment and provide exceptional customer service during the entire order process. Top quality customer satisfaction includes after-sales service. The most effective manufacturers provide expert help and support for that lifetime of a machine. This help may include shipping spares for repairs and providing learning machine operations for any workforce. Based on a customer's location, many manufacturers send their own personal engineers to your customer's factory to professionally install and commission the plant.

High-quality charcoal manufacturing machine is made of by far the most durable materials and use the latest carbonizing technology. Because of this, such machines can be used to process and recycle a wide variety of waste including MSW, sludge, rice husks, palm shells, coconut shells, palm kernels, sawdust, etc. High capacity machines can process over 3 tons of raw material each hour, and they also can operate continuously. A good quality waste biomass charcoal making machine can have a lifespan of 8+ years.

Carbonization Process

To guarantee good production efficiency, it's essential to pretreat raw materials before they can be fed in to the reactor of a wood charcoal making machine. So, biomass recycling plants have got a dryer and crusher. A dryer removes all of the residual moisture left in the raw materials, along with a crusher cuts the wood into small pieces. Needless to say, if a reactor is being fed with wood chips, a crusher is definitely not necessary.

The reason why the wood must enter into the biomass pyrolysis machine in small pieces is so that it is heated uniformly. Most charcoal maker machines use one fire two step heating designs, which means the residual heat from the reactor is utilized in the pretreatment drying system. This sort of design offers big energy-savings and therefore reduces a plant's running costs.

End Products From Wood Carbonization

The conclusion products from the carbonization of wood include charcoal, wood vinegar, and tar. Probably the most valuable of the is charcoal as it has many industrial uses. In agriculture, for example, you can use it to manufacture fertilizer or improve soil quality. In your everyday living, charcoal bring fuel for outdoor cookers and BBQs. However, the marketability of the other end products, wood vinegar and tar, should not be ignored. Both may be used in the chemical processes necessary to manufacture oil paint and mosquito-repellent.