About Tire Pyrolysis Plant Manufacturers in China

- By zhou qi

- •

- 08 Feb, 2020

In modern tires, there exists a steel wire that you ought to remove just before you get the tire to the reactor. The truth is, the steel wire is also another useful commodity, which you can instantly target steel factories and metal refineries.

The saddening truth is that the number of tires that individuals throw away as trash annually is significantly increasing worldwide. Since personal transportation is a necessity for modern lifestyles and cars tend to be more affordable, you will discover a vast number of vehicles currently on your way. That also means that it’s vital to dump most of the used tires safely.

Since there is an increase in popularity throughout the world for such waste tire pyrolysis plants, you are likely to realize a decline in environmental pollution by these waste tires soon. A large number of the well-recognized fully continuous pyrolysis reactor suppliers have generally exported products to many people customers in a number of countries, including India, South Africa, Indonesia, Saudi Arabia, Brazil, Romania, Philippines, UK, and many more.

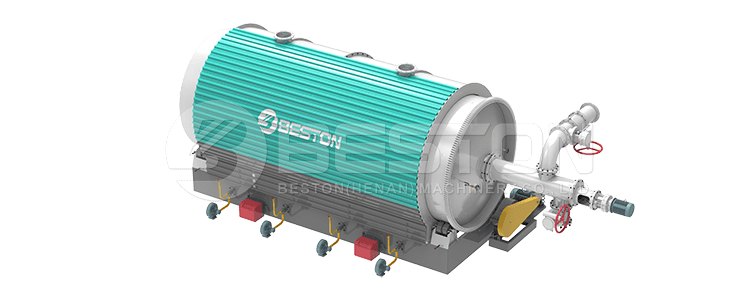

- Beston, in China, is probably the most popular pyrolysis plant manufacturers. Generally, the corporation produces a number of tire recycling machines to meet the requirements associated with a business, no matter the size. For example, they manufacture rotary reactors that are perfect for small-scale tire processing facility but they need considerably less floor area. What’s more, they could be cost-effective. However, the principle disadvantage with rotary pyrolysis reactors is they adopt a batch working principle, meaning that they can’t operate continuously.

When it comes to large-scale tire processing plants, fully continuous and automatic tire pyrolysis reactors are an outstanding option given that they can function 24/7 as well as process a lot of waste tire every week. With fully continuous models, you don’t need any cool-down period in-between different waste matter batches. Since feeding the tires to the reactor is automatic and constant, the possibility of the money you are able to achieve using these machines is very high.

Irrespective of the type of pyrolysis reactor you choose to use, you will need to shred the tires into considerably small pieces in order to feed them in to the sealed chamber. Since there are numerous grinding machines that you can get online at competitive prices, the costs vary based on several parameters.

If you would like obtain the best deal at prices, buyers should look into the suppliers found in China. They’re well-considered to be some of the most competitive prices of high-quality industrial machinery all over the world. Furthermore, international shipping charges are relatively more inexpensive, and this is the reason a great deal of manufacturers in China export to several foreign ports. More details can be found: https://bestonasia.com/waste-tyre-pyrolysis-plant/.